Our - Process

Highland Manor takes great pride in each one of our designs. However, the process begins long before metal touches wood to shape our parts.

Our designs begin as an idea before it is translated into a drawing. With more than 20 years in the industry, we have an understanding of what trends have stood the test of time and what trends are popular today. We rely on customer ideas and feedback to ensure that our line meets todays design standard.

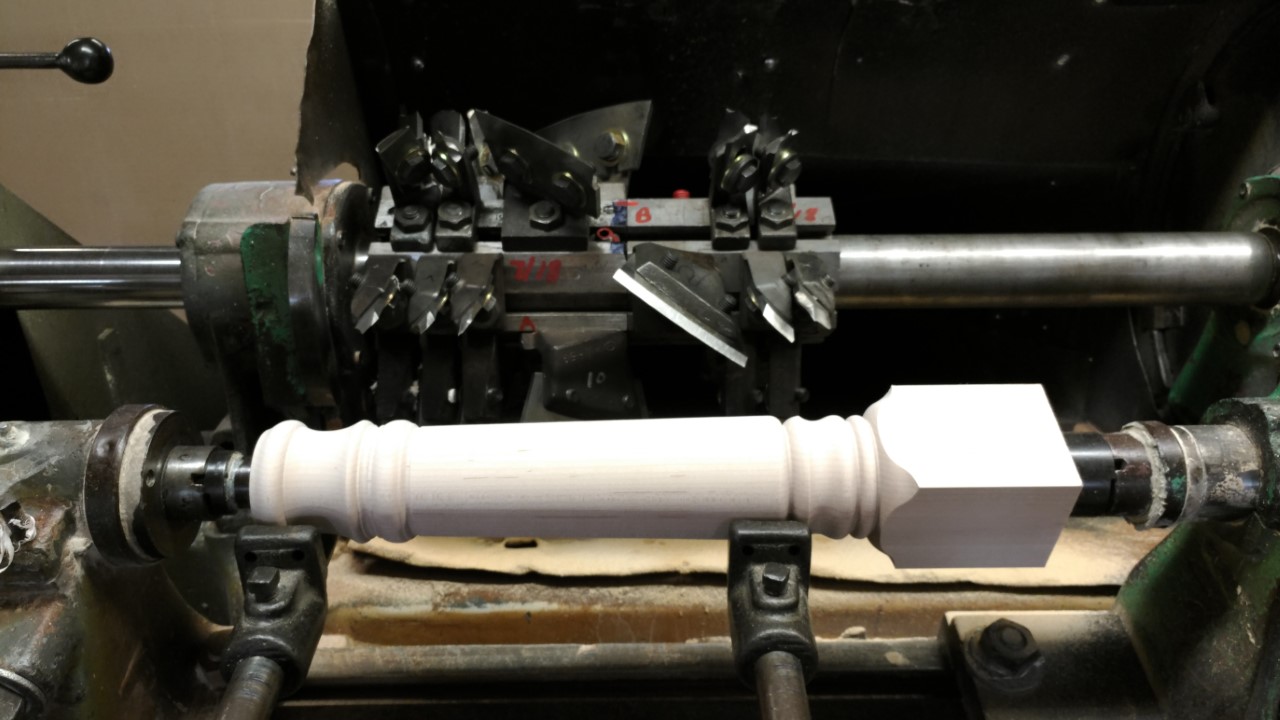

We use Mattison rotary lathes to turn our legs and feet, and each set of knives are ground by hand in house to ensure that every detail of every part is clean, sharp, and stunning. These knives are also painstakingly hand balanced. When the knives need to be sharpened, we don’t send them to an outside vendor- we also do that by hand in our grinding room. Some of our knife sets were originally built several years ago, and to ensure that they stay the same we always maintain them in our shop. They never leave, ensuring that you can order the same part in 10, 15, or 20 years and get the exact part. We set up and test each production run against an original part to ensure that this is always the case.

We hand sand each part with 150 grit sandpaper. Every part that ships out of our shop comes ready to be stained or painted and is inspected for any defects before going out the door. We stand behind our parts. If you are not happy with your order for any reason, contact us and we will work to make it right.

This is our process. It is a proven method to ensure that each part that you get from us, whether a stock part or a custom part that you design, receives the attention and inspection that it deserves.

Click here to follow a more in-depth view of our process.